| 1 |

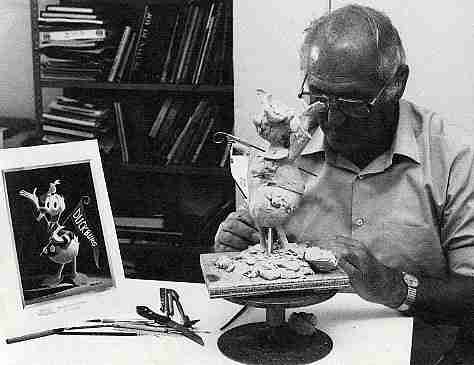

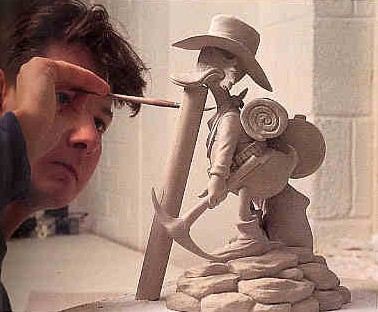

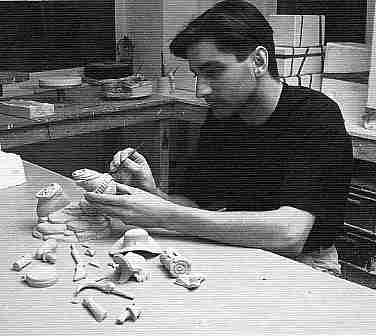

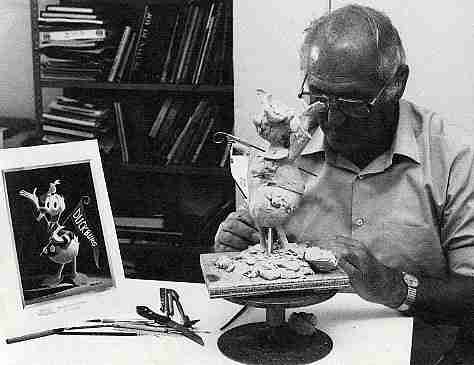

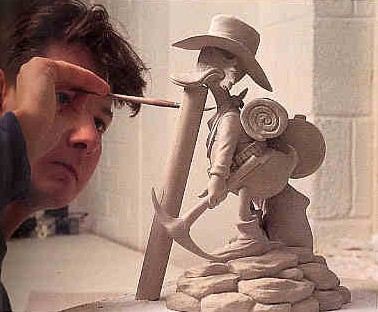

The

sculptor begins modelling a first rough figure in

plasteline. After completion it is dissected and

the parts used to create master molds. |

|

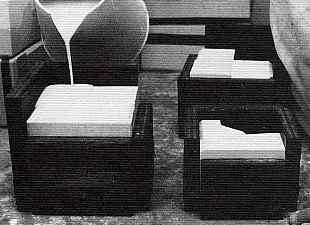

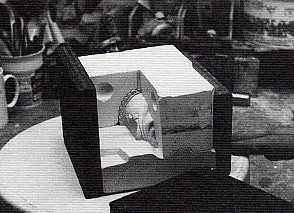

| 2 |

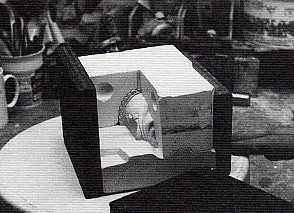

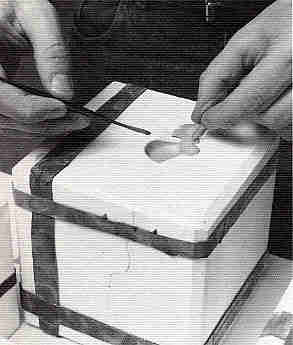

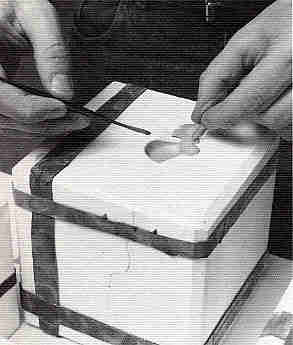

Part

of the frame is removed from the mold showing

three completed sections and the space where the

fourth will be poured. |

|

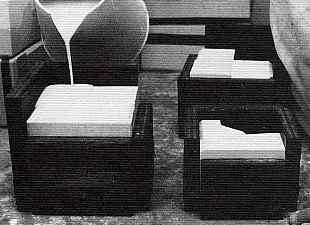

| 3 |

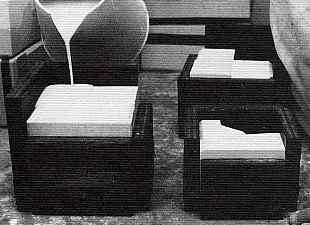

The

final sections of 3 of the molds are cast in

liquid Plaster of Paris. |

|

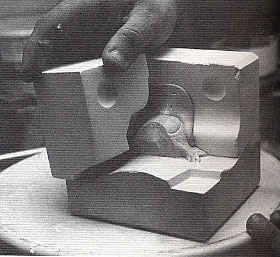

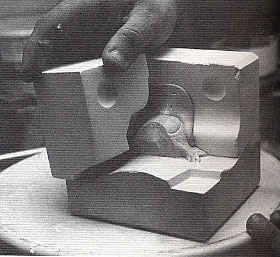

| 4 |

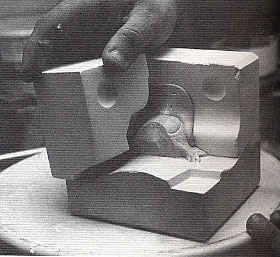

A

completed mold is taken apart and checked for

imperfections. |

|

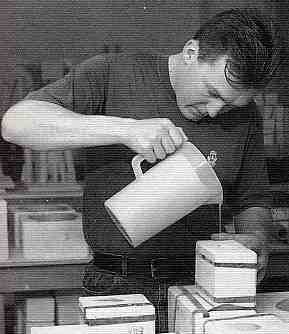

| 5 |

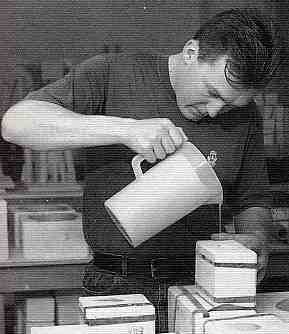

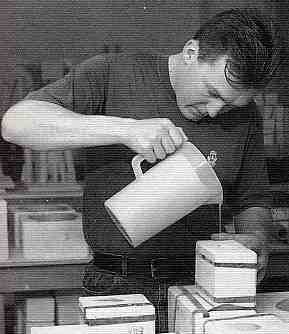

Liquid

clay is poured into each mold through a small

hole in the top. |

|

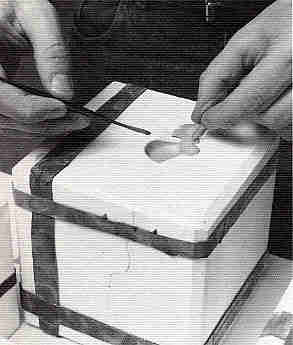

| 6 |

The

thickness of the cast is checked. Then the excess

clay is removed. |

|

| 7 |

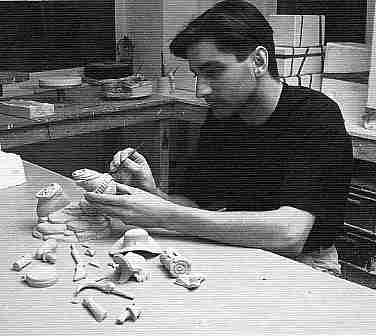

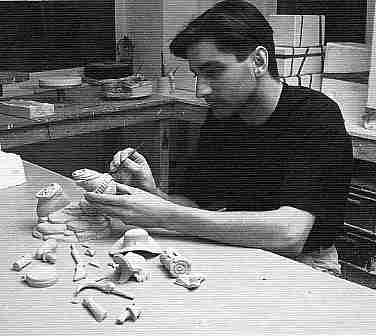

Before

the figurine is assembled, all the casting seams

are removed. |

|

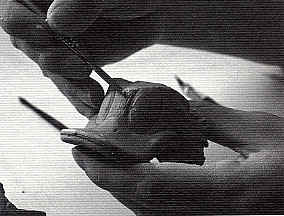

| 8 |

All

blurred details are meticulously sharpened by

hand. |

|

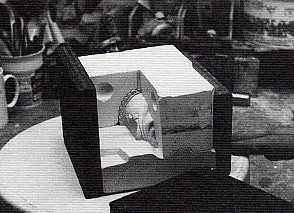

| 9 |

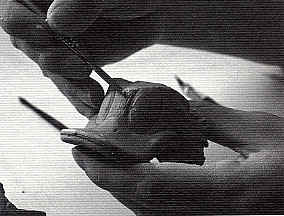

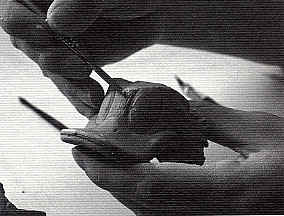

Scrooge's

head is gently positioned on his body. |

|

| 10 |

Then

it is secured with clay slip. |

|

| 11 |

Excess

slip is removed and the figurine receives a final

touch-up. |

|

| 12 |

Fully

propped, the figurine enters the kiln. |

|

| 13 |

Two

figurines - after and before the kiln process. |

|

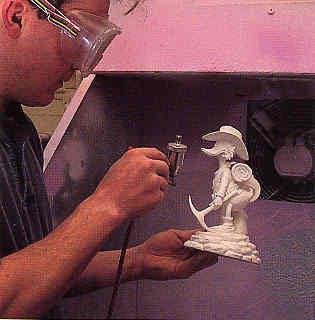

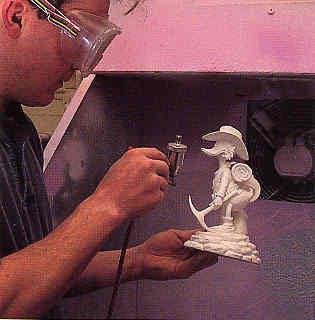

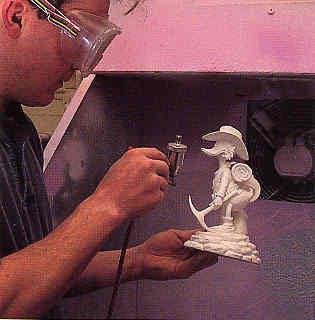

| 14 |

Bisques

are polished with repeated blasts of tiny glass

beads. |

|

| 15 |

A

painter carefully applies colour to the figurine. |

|

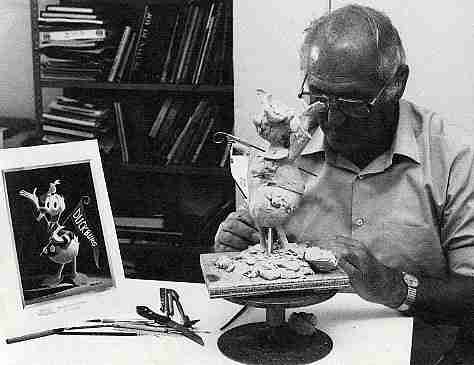

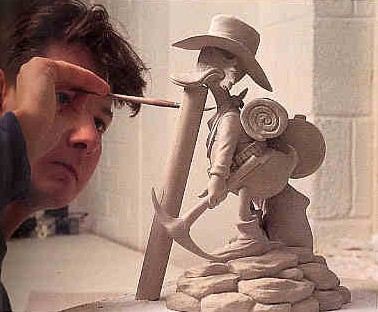

| 16 |

Now

Barks receives the prototype and he makes a few

corrections. |

|

| 17 |

Adding

a pale blue in the eye rim to avoid a staring

effect. |

|

| 18 |

Finally,

the prototype for the figurine is ready! |

|